You have been counting days till the wedding dress that you have ordered will arrive. Finally, it’s here! You take a moment to enjoy. Notice how soft it feels on your skin? How it fits your body and how incredible you look! Have you ever thought what it takes to create your wedding dress? We wish to share our values and work with you! Join us on a tour in SADONI atelier and meet our staff sharing how they prepare dresses. It is not just a phrase that love and laughter are sewn into them – it, indeed, is our passion here in SADONI.

It all starts with an idea.. Our designers have expertise feeling the bride’s needs; knowing various personalities and styles. We will talk about the design another time. For now we will share what happens in our atelier in Northern Europe behind the scenes once designs are prepared and fabrics ordered. In the simple way – imagine, you have good quality ingredients ready, but now the real art begins – how to put them together to create the most delicious result!

Our pattern maker and cutter SANDRA shares:

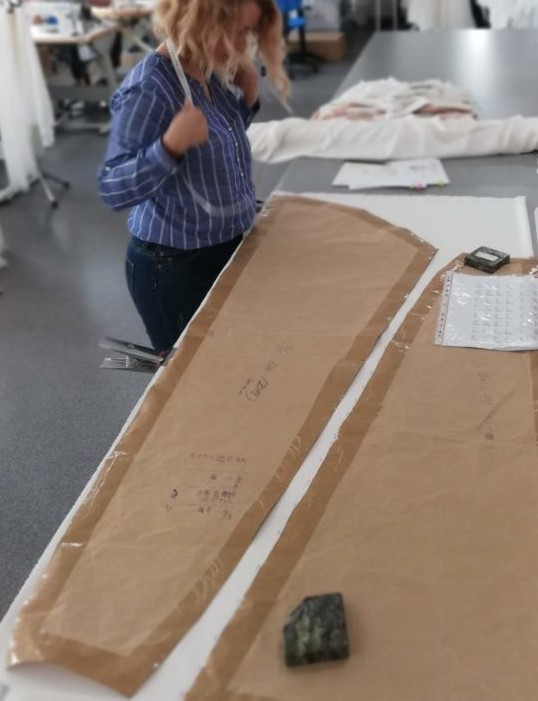

Once I receive the sketch from the designer and carefully look through, I take time to check fabric and imagine the outfit ready in my head. As we work with large rolls/amounts of fabric, there is a massive table that has been made especially for our needs. Paper dress patterns are hanging on the wall behind me, and each of them is labeled with the name of the dress. In order to access the fabric easily, it is stored under the table. Mostly it is in rolls: softest silk tulle, the most flowy silk chiffon, matte crepe silks, shiny silk satins, and different laces.

I gently pull out the fabric that particular design requests and lay it out. Each fabric behaves differently, for example, it takes a while before the light chiffon stays in its place and is ready to be cut. It is fun to watch its character. My hands mildly press it down with steel weighs/stones. The fabric is smooth and pleasant to work with. Next, I put on the pattern gently and mark it out with a special marker. If I work with lace instead of chiffon, it takes longer time as I need to follow the motive of the lace carefully to respect the original design. Afterwards, I cut out delicate lace motives. As many dresses are not standard size, we need to cut them individually. In cases there are more of the same – I use a machine cutter to cut many layers at once. Once I have cut all the parts of one outfit, I mark all pieces with the name and size. Next, I carefully wrap them together in a bundle not to loose anything and distribute to the seamstresses.

When it comes to seamstresses, they also have different strength and talent. As I have years of experience working with these skilled women, I can easily notice a talent of each seamstress. I know their strengths and can easily delegate them dresses that fit their expertise. Don’t get me wrong – they are experienced to create any dress from our collections, however, we also see what is the best fit for each. Some of our seamstresses are extremely patient and detailed oriented. They prefer to working with lace applications or making fine drapes in silk chiffon, or tulle as it’s very individual and creative process. Others are turbo speed sewers that finish all details perfectly in a short time frame.

Our seamstress DACE shares how the process continues:

I feel accomplishment from creating something handmade, it is my creative expression. Each of us seamstresses work on a dress from the beginning to finish. I take the fabric bundle labeled with the dress I am making, that one of the cutters has prepared for me. It is important to check the measurements continuously as I work to guarantee that it matches the size. Also, I need to make sure that fabric is in its best shape as natural silk has some irregularities. As I know the importance of the result, I care to do my best work daily.

Sewing is such a fascinating process and not boring at all; it has different stages and unexpected moments. For example, rushing over the long lines of the skirt or the dress is a lot of fun, as fabric may even be as long as 9 meters at the bottom hemline! And it also can be more detailed sewing – working with lace applications, crystals, exquisite details stitched by hand etc. During the sewing process I make sure that every seam is perfectly smooth in order to continue.

Lace applications and handmade drapes takes patience and time. It is a beautiful, but complicated work. Fine hand sewing is a characteristic of high-quality and is worth an effort. During the work we do, I cannot forget about good humour that our team shares. It uplifts to exchange positive energy!

It is exciting to see how the gown slowly is put all together. Stitching a SADONI label into the dress feels like a cherry on top, but it’s not done yet! I need to make sure everything is the highest quality and that the outfit sits well. A crucial part in the finishing process is steaming. I gently press down every seam with a high pressure steamer and it smoothes out the fabric beautifully. By embracing silk fabrics, steaming shapes the dress and brings it to life! It’s breathable, flowy and light! The feeling that I have been a part of someone’s love story gives me great joy.

As the evening slowly approaches, we see the sun setting from the atelier window. Steamers, machines and busy SADONI bees are slowing down, brand new dresses are elegantly hanging to be shipped away soon. On the way to you, to live out the purpose they were made for.